Operational review

Maximising our performance,

with an eye to the future

We operated under challenging circumstances for the entire reporting period. The worst is definitely behind us, and business is gaining momentum. However, what deserves a mention is our strong will to deliver, despite the headwinds.

Our manufactured capital comprises our countrywide network of integrated cement manufacturing and grinding units, ready mix concrete plants, offices and other state-of-the-art movable and immovable infrastructure, including warehouses, machinery and vehicles. The management of these assets is a key business imperative and is considered an important element in delivering manufacturing excellence and healthy operational performance.

The COVID-19 crisis disrupted supply chains and operations across the country during Q2 2020. To serve the needs of our consumers, we resumed operations in a phased manner in line with prescribed safety protocols. While resuming operations, we put in place various safety measures, from social distancing, touch-free handwashing to sanitisation of tools and vehicles to ensure the safety of our teams.

Overall, our cement business demonstrated encouraging performance, driven by stringent cost optimisation, efficiency improvements and better price realisation.

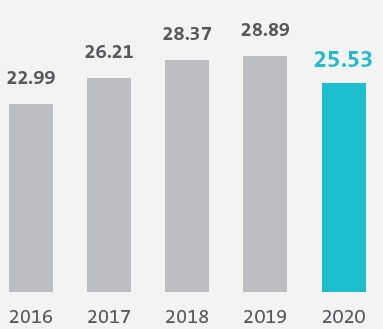

Cement Sales Volume (MT)

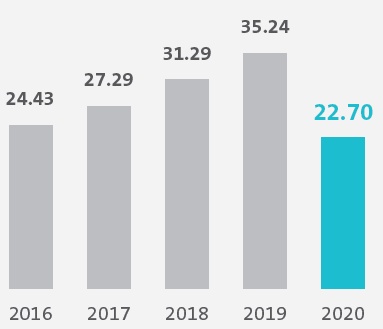

Ready Mix Concrete

Production Volume (Lakh m3)

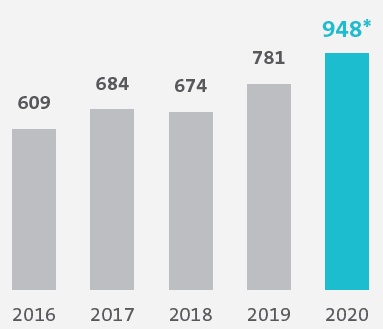

Cement EBITDA Per Tonne of Cement Sold (`)

*excluding charges of `129 Crore

CAPACITY EXPANSION AND CAPEX PROJECTS

With cement demand projected to rise significantly in India, development capex projects were kickstarted to increase clinker and cement capacities in the attractive and highly profitable central region of India. This, in turn, will ensure that we have ample capacity to cater to a rising demand scenario.

Clinker unit

2.7 MT

AMETHA, MP

Grinding unit

1.0 MT

AMETHA, MP

2.2 MT

SHONEBHADRA DISTRICT, UP

1.6 MT

TIKARIA, UP

1.4 MT

SINDRI, JHARKHAND*

*Commissioned in January 2021

PARVAT

Parvat is an efficiency optimisation programme initiated in 2019 to bring radical changes in the cost structure and to improve delivered cost. Our plants help us deliver on the expectations of our esteemed customers. Therefore, it is only natural that the execution of ‘Parvat’ is in line with the requirements of our plants.

2020 saw us conducting workshops and brainstorming sessions, assisted by an external consulting agency at all our plants across the country. Simultaneously, the leadership took turns to visit different plants to explain the underlying intent and the overarching objective of ‘Parvat’ to our people.

Once the direction was set, the potential savings from the identified initiatives were calculated by the finance department and projected as monthly targets. The ideas were reviewed in marathon sessions with cluster managers and plant directors. The ideas shortlisted were entered into a business intelligence tool, especially created for the management to review all initiatives.

Following the roll-out, progress across these initiatives was mapped every month and at various levels. These reviews helped pre-empt the roadblocks and remove bottlenecks and catalysed better decision-making. Even as the COVID-19-induced lockdown threatened to slow the progress, the teams were quick to resume in full spirit, as soon as the restrictions were lifted. As a result, in 2020, about 500 initiatives were implemented successfully in manufacturing alone.

SUPPLY CHAIN AND LOGISTICS

Our logistics strategy is based on four pillars, which include distribution safety, cost efficiency, use of technology and environmental sustainability. We engage with suppliers, governments, industry bodies, businesses and other partners to collaborate and find new ways to innovate and create positive change.

At ACC, we aspire to create a supply chain mechanism, which is agile, cost competitive and sustainable, leading to customer delight. Our logistics team drives various initiatives at each node to ensure that the distribution network is constantly evolving across services, cost and sustainability.

Case Study Supply chain automation and optimisation

To accelerate automation and optimisation in our supply chain, ACC and Ambuja Cement launched a strategic and all-encompassing supply chain project in partnership with Blue Yonder – the world’s leading, end-to-end, digital supply chain platform provider.

The initiative is aimed at:

- Generating monthly demand plan based on forecast from grassroots level

- Consensus planning resulting in better capacity utilisation

- EBITDA maximisation by shifting volumes from low to high EBITDA markets

- Network optimisation to improve services and boost secondary distribution cost

- Framework for strategic simulation to facilitate decisions related to future expansions

The initiative will maximise EBITDA by effectively using technology for capacity utilisation improvement, shift from low to high EBITDA markets, and enable cost optimisation and improved customer services.

To modernise and enhance our supply chain, we:

Focused on digitalisation through the ‘Plants of tomorrow’ initiative. We implemented Technical Information Systems (TIS) that record minute-by-minute data from all key assets at the plants

Performance And Collaboration Tool (PACT), a cross platform dashboard/decision support system to view critical parameters from TIS data, collaborate and take actions on alerts, has also been implemented at all plants.

EDGE AI has been implemented in some of our plants as an advanced analytics platform to facilitate integration of all Machine Learning (ML) and Artificial Intelligence (AI) initiatives.

This has helped improve operations, generating automatic alerts and has laid the foundation for implementing Industrial Internet of Things (IIoT) use cases. We also piloted the use of AI/ML into predicting cement strength, fineness and predictive maintenance of critical equipments like Vertical Roller Mill (VRM)

-

Launched an integrated planning tool that enables, sales & operation planning and network optimisation to improve customer service, cost optimisation and organisational profitability

-

The extensive use of Transport Analytics Center (TAC) has helped in real-time information dissemination and analytics to improve distribution safety, cost optimisation and operational efficiencies

-

Enhanced the ‘Dealer Connect App’ with additional functionalities like real-time tracking of deliveries, faster ordering and improved and timely communication

Improved the functionalities of ‘Concrete Club app’, a singular social platform for construction professionals such as architects and engineers to connect, interact and share knowledge with each other, with dashboards for regional teams to run loyalty programmes

Utilised the digital platforms to share invites to knowledge series initiative, where experts from construction and building industry shared their learnings and expertise with these influencer segments through webinars

Developed digital kit comprising e-visiting cards, e-catalogues and posts to promote app adoption for the influencers and internal stakeholders

Undertook continual measures to build a better fuel mix by maximising the use of cheaper fuel through judicious procurement of coal from the market through

e-auctions and imports; higher consumption of alternative fuels and improvement in competencies and efficiencies at plants