Strategic review

S3

S3Delivering superior

performance

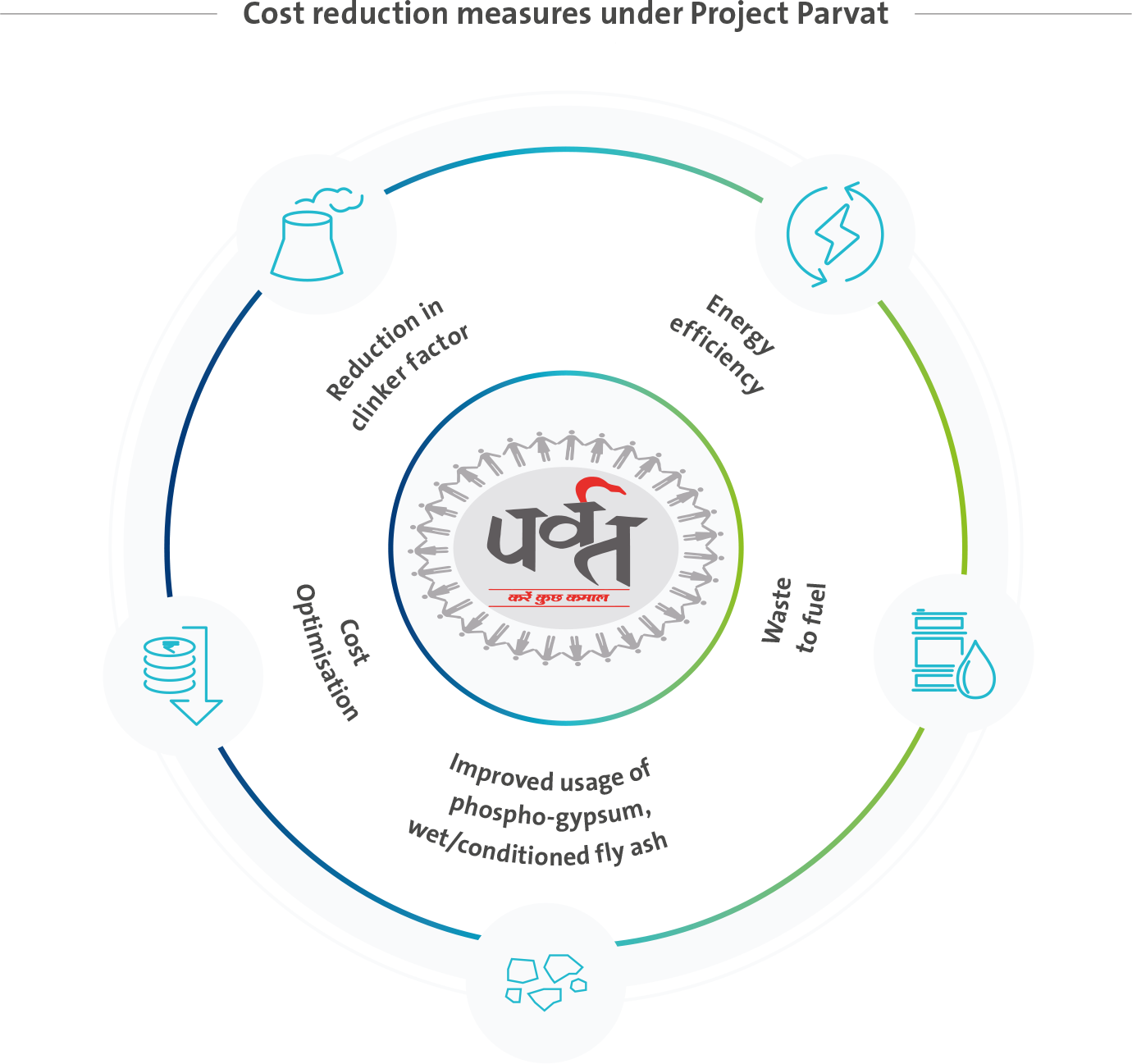

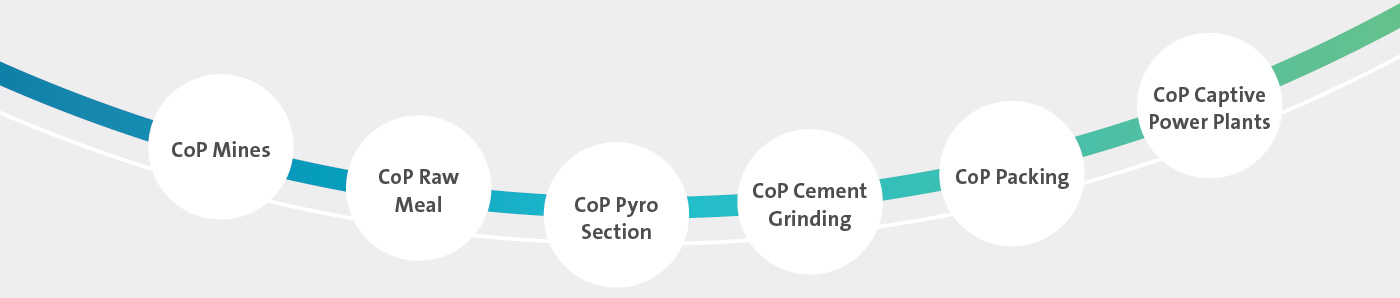

With this strategy, we aim to continue delivering superlative business results while bringing superior products to the market and contributing to nation-building. This lever focuses on enhancing the performance of our existing portfolio, improving our cost efficiency, strengthening our people capabilities and mainstreaming digitalisation to drive greater efficiencies.

Material issues addressed

12 21

12 Economic performance 21 Climate & Energy

SDGs impacted

PERFORMANCE DURING THE YEAR

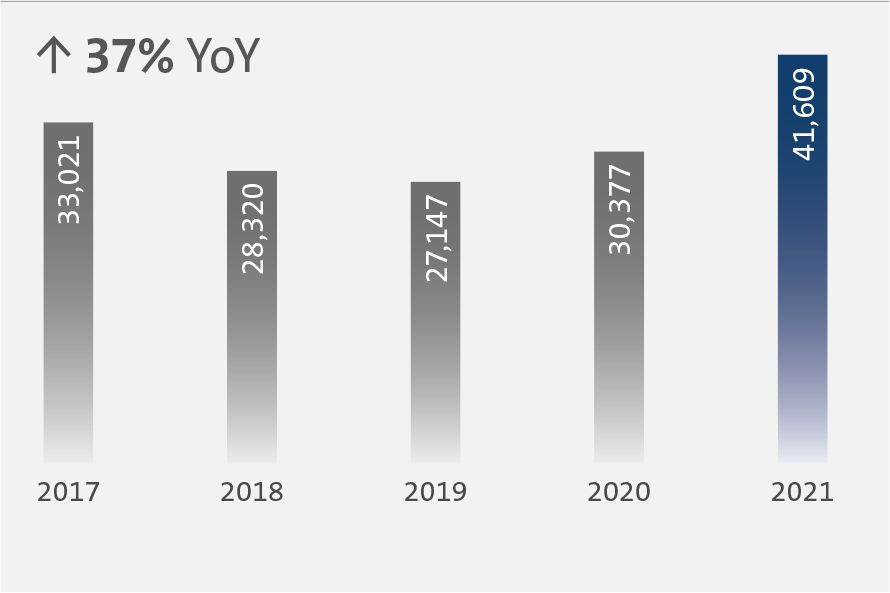

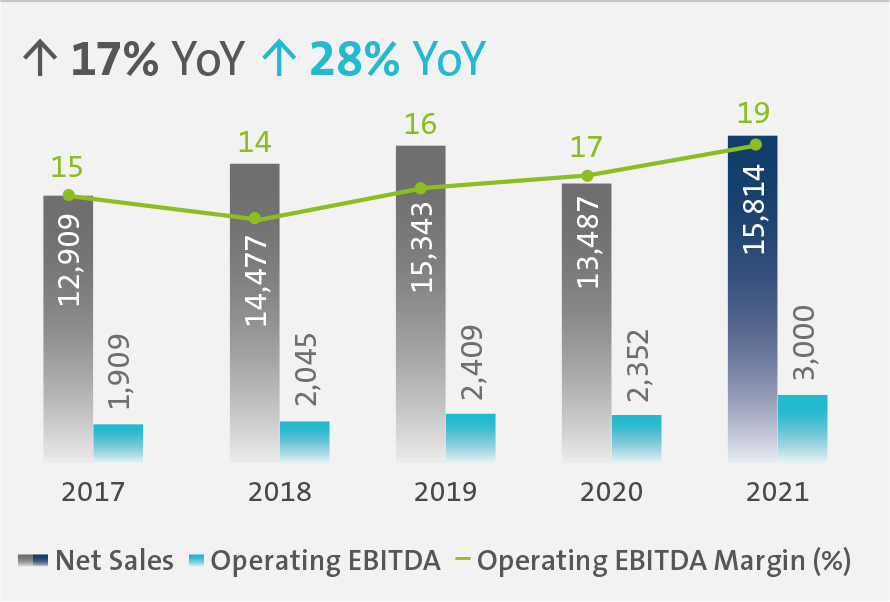

Net Sales, Operating EBITDA &

Operating EBITDA Margin* (` Crore)

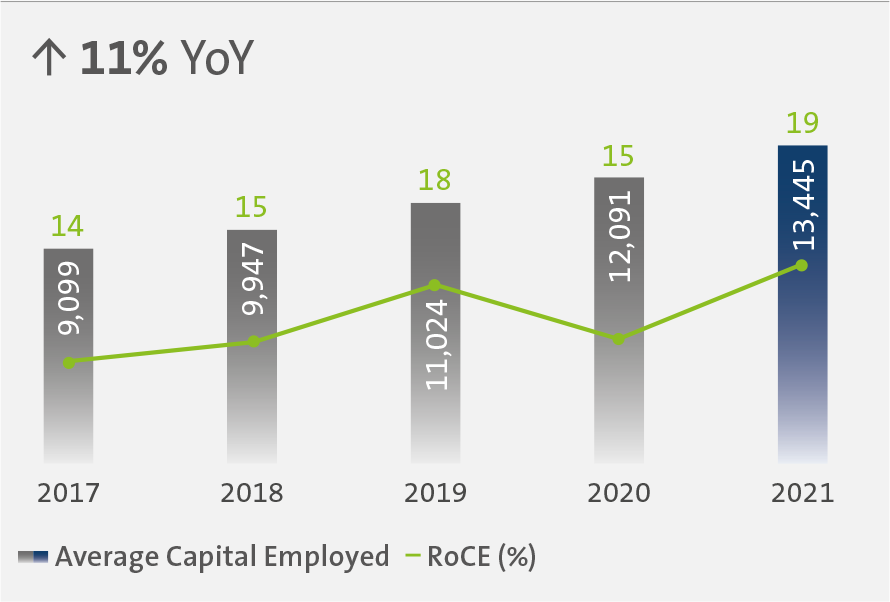

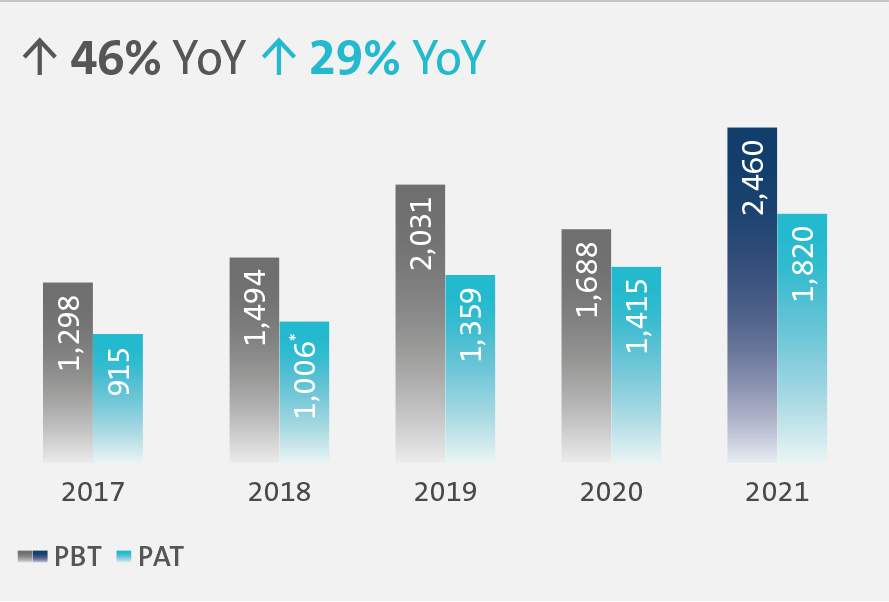

Profit Before Tax (PBT) &

Profit After Tax(PAT) (` Crore)

*Excludes write-back of `501 Crore related to tax provision

CREDIT RATINGS 2021

Fund Based

Non-Fund Based

CRISIL AAA/Stable

CRISIL A1+