PILLAR 2

Circular economy

We promote circular economy and aim to contribute to it with our Geocycle brand. Through Geocycle, we offer safe waste management solutions for the use of industrial and municipal wastes in our kilns. We work closely with municipalities for managing municipal solid waste.

We prioritise the management of single-use plastics through co-processing, which helps to keep them out of landfills and rivers. ACC has seven co-processing kilns in its plants with an annual capacity of over 5 lakh tonnes of waste, helping to generate alternative fuels and raw materials.

Making India free of single-use plastic

Single-use plastics are non-recyclable and end up polluting land and water bodies for many years. As part of our single-use plastic management exercise, Geocycle undertook stadium clean ups after cricket matches and supported its drive with impactful campaigns to generate awareness about the long-lasting negative impact of single-use plastics.

Leave Behind no Waste (#LBnW) brand campaign

As a firm step towards our Net Zero vision, ACC launched the 'Leave Behind no Waste' campaign this year (#LBnW - which also stands for a type of dismissal in cricket), by collecting and responsibly disposing off all single-use plastic generated during the India vs New Zealand test match in 2021.

The campaign used traditional and digital platforms to amplify the message of making sports more sustainable so that our planet is a better place to live in for future generations.

2 tonnes per day of single-use plastic collected during the India vs New Zealand test match in 2021, was disposed responsibly through co-processing in our kilns.

Categories of industrial, municipal and other wastes utilised by ACC

Sludges from automotive and engineering sector

Expired goods from FMCG and food and beverage companies

Sludge and catalysts from oil and gas industry

Process rejects from aluminium, steel and power industry

5 Lakh+ tonnes

Industrial, municipal and plastic wastes were co-processed in 2021

Geocycle helps Himachal Pradesh in ‘Zero plastic’ initiative

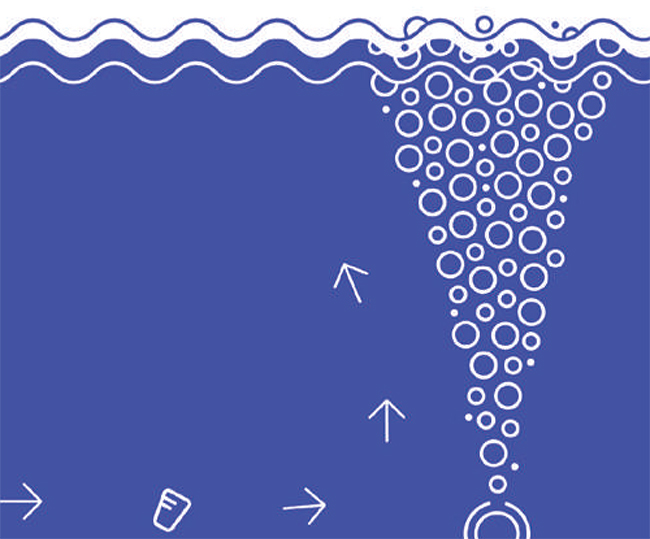

The Himachal Pradesh government launched a state-wide campaign to clean up plastics from the mountains. Geocycle supported this campaign by co-processing the plastic collected from various districts in ACC’s cement kiln at Gagal, thereby helping the state progress towards its zero plastic goal. Now, Geocycle is setting up a Bubble Barrier in Himachal Pradesh to collect plastics from the Beas river.

Collecting and reusing our packaging material

Cement packaging material has high reuse value in construction sites for storing materials and as roof coverings for the poor people's homes. ACC collects used or torn cement bags and co-processes them as alternative fuel in some of its manufacturing units.

Bubble Barrier Technology

Co-processing waste

Utilising Municipal Solid Waste (MSW) from communities

The municipal corporations at Kalburgi and Bidar in Karnataka faced challenges in managing the disposal of plastic and other dry waste categories. The lack of proper waste management solution led to accumulation and storage of such waste, creating the need for an efficient disposal mechanism.

ACC Wadi signed a Memorandum of Understanding (MoU) with these municipal corporations. With support from Geocycle, these waste categories were safely transported and co-processed at our Wadi plant. This joint initiative by ACC and Geocycle was greatly appreciated by the local bodies.

The clean up also touched thousands of lives, and provided the people living in this region with a cleaner and waste-free environment.

Legacy waste management

India has over 3,000 landfill sites, covering more than 10,000 acres of land. These sites pose serious hazards for the environment and public health. They are a source of foul odour, greenhouse gas emissions and groundwater contamination.

ACC is working with municipalities to help remediate legacy dumps by co-processing their segregated combustible fractions in kilns at ACC cement plants.

90,000 Tonnes

waste utilised from landfill sites

Implemented across 60+ sites, remediating more than 300 acres of land space.

Co-processing focus areas for 2022

- Focus on footprint expansion for managing Municipal Solid Waste and plastic waste across the country.

- Working in remote villages that are located close to our plants and help them manage their Municipal Solid Waste in a scientific and environment-friendly way

- Capacity expansion across all plants to enable higher utilisation of waste volumes in the kilns.