PILLAR 3

Environment

ACC takes a multidimensional approach to safeguarding the environment. We minimise our air emissions, promote biodiversity, and recycle water to reduce our environmental footprint. At the same time, we take active efforts to nurture and green our surroundings.

Air emissions minimisation

We have installed advanced primary and secondary abatement measures in addition to regular maintenance of equipment at manufacturing locations to minimise air emissions. This helps us to comply with the Emission Limit Value (ELV) mandated by various regulators. We have installed Continuous Emission Monitoring systems (CEMs) at all our 17 cement plants to monitor air emissions. Air quality is also monitored through the Continuous Ambient Air Quality Monitoring Stations (CAAQMs).

CONTROL OF EMISSIONS AT OUR PLANTS Dust

We have achieved continuous improvement in process efficiency. We have high efficiency bag filters in all operational processes, except Clinker Cooler application. We also use latest Electrostatic Precipitators (ESPs) in Clinker Cooler application. We adhere to periodic maintenance schedules for all processes and systems.

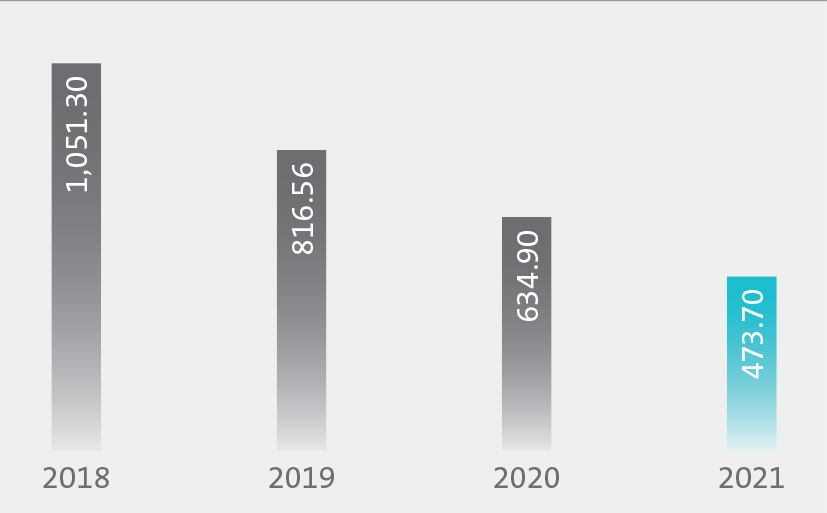

Dust Emissions

(g/t of cement )

SOx

The inherent presence of high lime content in cement manufacturing process helps in absorbing SO2 emissions.

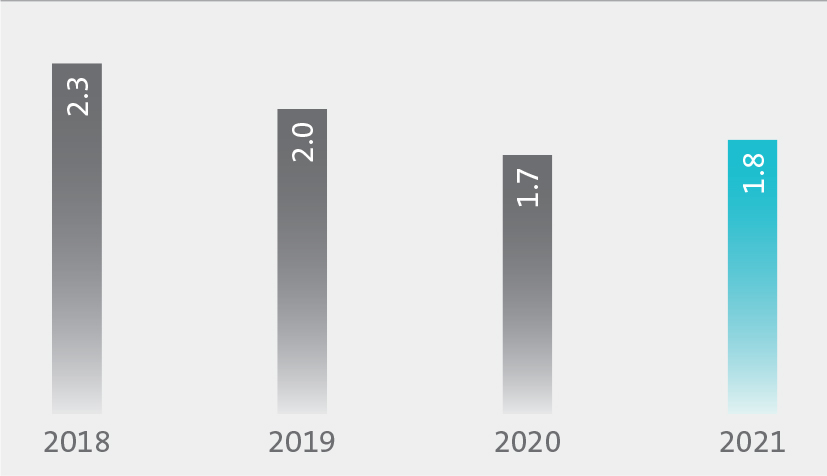

SOx Emissions

(g/t of cement )

Note: There is a significant increase in SOx emissions intensity in the year 2021 as compared to 2020.This is due to change in raw material quality and change in fuel at Chanda. There is some increase in dust emission for the year 2021 due to some operational problems in few of our plants. However, the specific emissions are in compliance to regulatory norms.

NOx

We are improving operational and process efficiencies through implementation of various primary measures for controlling NOx emissions. Our integrated plants use Selective Non-Catalytic Reduction (SNCR) systems for sustainable operations.

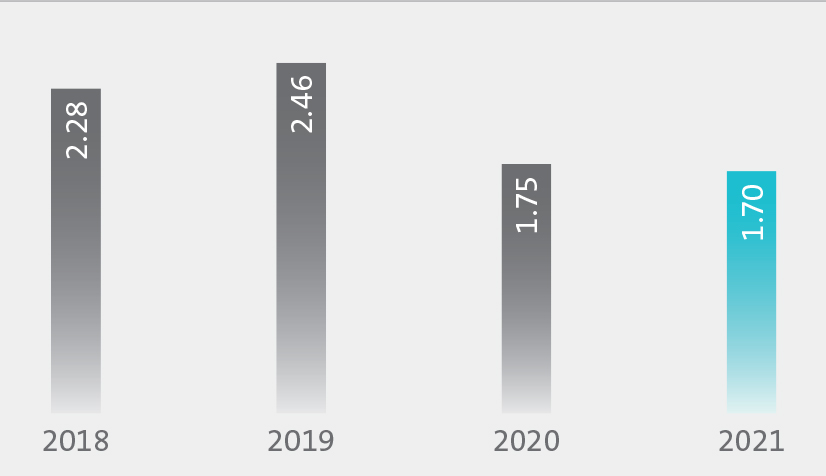

NOx Emissions

(g/t of cement )

Mercury Emissions

Maintaining compliance with the regulatory Emission Limit Value (ELV) for mercury and its compounds’ emissions. Kiln is the source of mercury emissions from cement manufacturing operations. Compliance levels for all our kilns was at <0.5 µg/Nm3, as is prescribed by Ministry of Environment, Forest and Climate Change (MoEF&CC).

Developing forests at our plants

In the past 3 years, ACC has developed forests at Chanda and Wadi manufacturing plants using the Miyawaki technique. Inspired by the growth of these forests, we undertook another forest development at Wadi plant in 2021 in an area of 250 m2 using Miyawaki1 technique.

- Miyawaki method is developed by Japanese scientist Mr Akira Miyawaki, and is useful in creating forest in shortest possible time

Water and wastewater management

Water is integral to life. We are conscious about the water scarcity experienced in various parts of our country and the impact of climate change worsening the situation. At ACC, we adopt a multi-dimensional approach to return more water than what we consume at our plants and are 1.35 times water positive. We return water to communities through our community water harvesting structures including converting mined out pits into reservoirs.

OUR WATER MANAGEMENT STRATEGY

Optimising water consumption in our plants

Specific water consumption reduced from 151 Litres per ton of cementitious material in 2020 to 136 Litres per ton of cementitious material in 2021.

Zero liquid discharge from our operations

During the year, we used 0.57 Million m3 of recycled water and reduced our specific fresh water consumption from 78 Litres per ton of cementitious material in 2020 to 74 Litres per ton of cementitious material in 2021.

Rainwater harvesting in our mines

In 2021, we have harvested 16.2 Million m3 of water in our mine pits/voids.

Rainwater harvesting in communities

In 2021, we have created community rain water harvesting structures, resulting in harvesting 1.9 Million m3 of water.

Water harvesting at Bargarh Mines

Water management performance

Surface Water Consumption

(Million m3)

Harvested Rainwater Consumption

(Million m3)

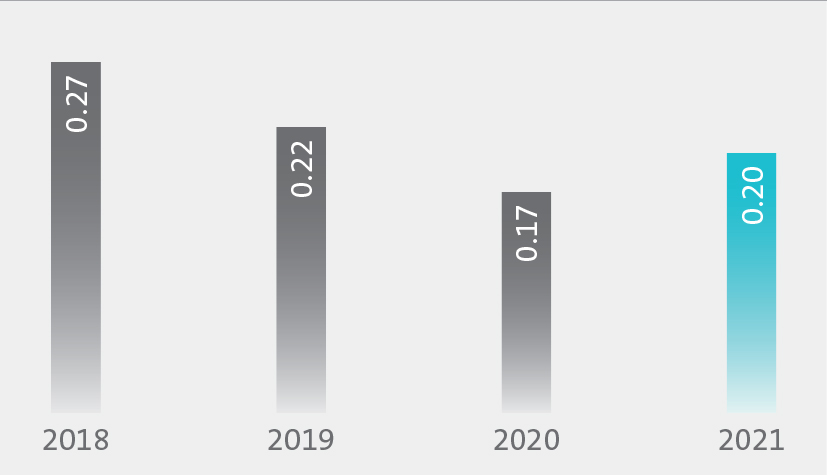

Groundwater Consumption

(Million m3)

Biodiversity

Assessing and improving biodiversity is important for us, across our operations in plants and mines. We have conducted biodiversity assessments at all 17 plants, using the Biodiversity Indicator Reporting System (BIRS), a tool developed by Holcim, in partnership with International Union for Conservation of Nature (IUCN). BIRS is a standardised system for assessment and regular monitoring of biodiversity at any extractive operation site is possible. Based on the outcome, various remedial measures are implemented in the mines. As the COVID situation eases in 2022, we plan to reassess our mines using the BIRS tool.

Three of our mines, Lakheri, Dungri and Gagal, are located within a 10 kms-radius of certain nationally protected areas. We have developed and implemented Wildlife Conservation Plans (WCPs) for all these mines to maintain ecological balance. Additionally, we have made WCPs for our Sindola and Govari mines.

As a responsible corporate, we strictly adhere to the commitments made in our mining plans and regularly undertake plantation activities at our mines, mined-out pits and dumps to manage and conserve biodiversity. Our mined-out pits not only act as water reservoirs but also help in conserving local ecology. We plant around one Lakh saplings every year across our operational sites.

A few of our initiatives also focus on the conservation of particular flora and fauna at certain plant locations. Under the ‘B-Buzz’ project, we are developing a butterfly garden, a fruit garden, and also doing invasive species management.

Awarded five-star rating by Ministry of Mines for sustainable mining

ACC’s limestone mines at Govari, Wadi, Gagal, Jamul and Kymore were felicitated with the prestigious ‘5-star rated mines’ award by the Ministry of Mines, Government of India, at the 5th National Conclave on Mines and Minerals. From nearly 1,029 mines assessed across India, our mines were recognised for their sustainable mining including scientific and systematic mining practices, progress on mine closure plan, addressing of resettlement and rehabilitationissues, local community engagements and welfare programmes.