Manufactured Capital

Strong Foundation,

Stronger Structures

Competent management of our manufacturing assets is crucial for operational efficiency, profitability, and growth. Simultaneously, we remain dedicated to responsible manufacturing by reducing resource and energy consumption, embracing cutting-edge technology and safe practices, and consistently adhering to environmental regulations.

`1,514 crore

CAPEX spend on development and efficiency

Material issues addressed

- Land acquisition for mines and new plants

- Operational efficiency

- Sustainable construction

SDGs impacted

Key Highlights

Freight and Forwarding Expense (FFE) maintained at the same level of last year (K1257/t in Jan’22 to Mar’23 vs. K1262/t in 2021) despite headwinds of HSD price increase ~4% and railway busy season surcharge (+15%) from October 2022

PAN India warehouse network optimisation increased direct dispatch to customer by 2%

Initiated UDAAAN Project for logistics cost rationalisation to unlock group synergies and leverage technology

Commissioned brownfield grinding unit at Tikaria in February 2022 and scaled up dispatch to highest ever volume of 346 kMT in March 2023

Development and Efficiency

At ACC, we are committed to continuously investing in strengthening our market position and evolving into a more efficient, cost-competitive, and environmentally sustainable organisation. Some of our key initiatives this year include:

Capacity Expansion

Commissioned Tikaria Plant-2 of 1.6 MTPA capacity

Ametha Integrated Unit is in advanced stages and will be commissioned in FY24

Raw Material Security

Kannur Wadi Limestone Block in Karnataka

Kurai Limestone Block in Maharashtra

Gothra West Limestone Block in Rajasthan

Behera-Banjipali Limestone Block In Odisha

Mudhvay Sub Block-C Limestone Block

Capacity Expansion

Installation of WHRS of total 22.4 MW capacity at Jamul and Kymore of over H300 crore

Further installation of WHRS is planned in Ametha, Wadi & Chanda with total capacity of 55.8 MW.

100 MW solar energy for various locations of ACC

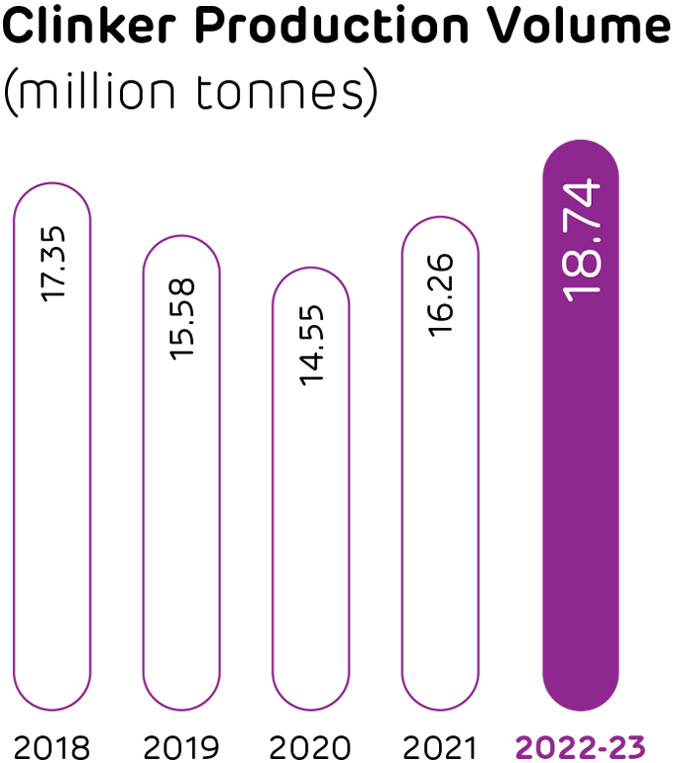

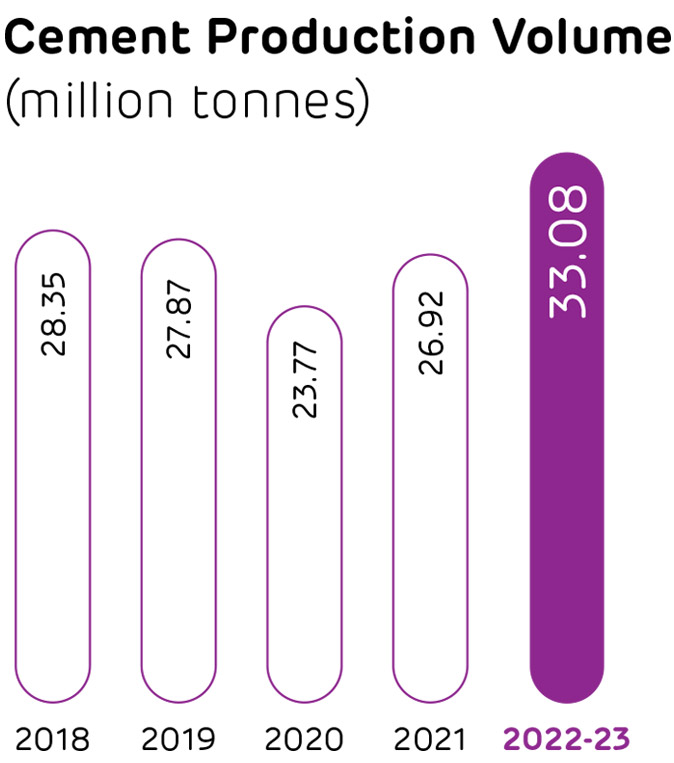

Manufacturing Performance

We achieved several notable accomplishments this year, which have resulted in better operational efficiencies like a decrease in clinker factor by 1.5% and a reduction in electrical energy consumption by 2.16 kw/t cement (total).

Efficiency Improvement

We strive to be one of the most cost-competitive cement manufacturers in the country and to achieve this goal, we consistently invest in various areas of our operations. These include several initiatives, such as reducing our clinker factor, enhancing energy efficiency, optimising our raw material and fuel blends, improving our power sources, and expanding the utilisation of alternative fuels and raw materials in our manufacturing processes. We have incorporated approximately 14.62 million tonnes of waste-derived resources, including 0.82 million tonnes from Geoclean, into our manufacturing operations. This aligns with our commitment to reduce our reliance on natural resources and promote sustainability.

Plant Efficiency

- Reduction in electrical power consumption achieved through optimisation of grinding media charging and optimisation of grinding aid consumption, resulting in reduction of energy requirement by 1%.

- Installation of VFD’s in clinker cooler, new high momentum burner and optimised product production distribution has helped us to reduce the energy required for clinker by 2%

- Computational Fluid Dynamics (‘CFD’) studies and implementation of findings by in-house modification also help to improve efficiencies

Cost Rationalisation

- Maximisation of Wet Fly Ash (WFA) and Conditioned Fly Ash (CFA) usage to reduce overall fly ash cost

- Replacement of 50% traditional High Speed Diesel usage with Pyrolytic Oil at the time of cold kiln startup

- Maximisation of alternative fuels and raw materials to reduce fuel cost

- Optimisation of raw mix in fuel to reduce overall cost of cement

- Use of molecule-based grinding aid to reduce procurement from vendors

- Maximum utilisation of fly ash to reduce clinker factor

- Kiln Master and Mill Master (Advanced Process Control) commissioned for better mill performance

Product Quality Management

Our quality parameters are stringent, and we closely monitor them to continually improve our overall Product Quality Index (PQI). Our product quality monitoring strategy involves daily testing of defined quality parameters, measurement of coefficient of variations at three-day and 28-day intervals, clinker quality assessments, customer satisfaction surveys, bi-monthly product benchmarking, bi-monthly application-oriented product testing, monthly testing of random market samples, and monthly assessments of bag quality index.

We comply with all statutory requirements as mandated by the Bureau of Indian Standards (BIS) as well as all weights and measures norms. As part of our statutory compliance, our bags display our contact details to enable customers to communicate any complaints, observations, or queries.

Key Initiatives To Improve Overall Process/Product Quality

- Cross Belt Analyser installed for real-time quality check of limestone from mines

- Technical Information System (TIS) implemented for production and lab data information

- Molecule-based grinding aid used to improve cement strength

- SO3 optimised across locations to improve strength

- X-ray Diffraction Meter (XRD) used for qualitative and quantitative identification of clinker phases for strength optimisation

- Robotic lab is planned for real-time quality monitoring and control of cement manufacturing at Ametha

Supply Chain and Logistics

We leveraged digitalisation initiatives across the supply chain to optimise costs. We also used best-in-class tools for network optimisation, sales & operations planning, and e-platforms for freight procurement. All our logistics excellence projects are managed through automated dashboards.

Freight Reduction

We are taking various initiatives to improve efficiency and negotiate contracted rates. We use the latest e-procurement platforms to get real-time freight rates, and closely monitor vendor performance to improve their value proposition

Safety and Sustainability

We have re-opened our Driver Management Centres (DMCs) to engage with the driver community and promote safety-oriented behaviour. Transport Analytics Centre (TAC) has helped us develop more meaningful safety dashboards for use by the DMC. Additionally, we are developing a Carbon Reduction tracker and working on bio-fuel trials, e-vehicles, lead reduction, and mode mix to reduce our carbon footprint. In-plant automation through RFID has helped to augment efficient and safe fleet movement inside the plant as well.

Captive Power Generation

We have taken strategic initiatives in our value chain to ensure efficient energy sourcing and have developed in-house capacity to meet our energy requirements. We are utilising alternative fuels/biomass, waste heat recovery (WHR), and renewable energy sources such as wind and solar. Additionally, we have implemented an energy management system (ISO 50001:2011) to improve our energy efficiency. A significant portion of our power consumption is generated through our captive power plants.

We have successfully increased our in-house power generation by 3%, which includes a 1% reduction from CPP and a 139% increase in WHRS. We have also approved further investment in WHRS, and the progress is well on track.

Mining

We have ensured that all our integrated cement plants are associated with captive limestone mines to secure our major raw material.

Our Company policy strictly prohibits operations in the immediate vicinity of specific biodiversity zones, world heritage sites or International Union for Conservation of Nature (IUCN) category I-IV protected areas. We have a Biodiversity Action Plan (BAP) for sensitive sites. Additionally, we undertake a biodiversity indicator reporting system (BIRS) assessment every three years, as per IUCN guidelines, and prepare an improvement/ action plan.

We always aim to resolve any issues with the local community through dialogue and negotiations. We are proud to report that there were no strikes or lockouts at our mines during the reporting period.

Ensuring Optimum Utilisation of Mineral Resources at Captive Mines

- Maximise the use of alternative and waste derived materials in the process

- Achieve ZERO waste mining

- Properly blend low-grade and high-grade material to optimise resources and maximise mine life

- Using eco-friendly mining techniques such as application of surface miners for Coastal areas, with no use of blasting

- Conserve mineral, water, and other natural resources

- Practice safe development and operation in each mine

- Employ environmentally friendly mining equipment with minimal exposure of workers to health and occupational hazards

- Maintain effective and efficient mining and extraction processes while preserving ecological balance

- Utilise limestone screening and extraction methods.

Key Initiatives Undertaken in the Mines

Kymore

- Diverted the Garland Drain along the mine boundary to have a permanent solution to every year shifting within the mine. This has maximised resources and improved the quality of limestone for plant requirements and systematic mine operations

- Increased the lifespan of our dumpers’ tires by converting failed tubeless tires into tubed tires, thereby optimising costs

- Optimised lead and lift, and used fuel-efficient equipment, along with proper planning of excavation to reduce diesel consumption and save costs

Wadi

- Optimised our mining cost and conserve fuel by using FE Oil in HEMM up to 30%, which replaces fossil fuel

- Conserved mineral and utilised waste by utilising intercalation of clay in interburden without beneficiation

- Reduced diesel usage and effectively utilised waste oil in explosive preparation by using BMD vehicle

Chanda

- Optimised the cost and improved systematic mining at Gowari mine by reducing the lead for overburden handling by 1 kilometre

- Optimised mining cost and conserved fuel by using FE Oil in HEMM up to 30% as a replacement for fossil fuel

- Started a new pit in Sindola Mine with a lower Strip Ratio from 1.78 to 0.8 of higher LSF, which resulted in a reduced cost of mining

Jamul

- Initiated trials to use FE Oil for HEMM, and have reached up to 50% usage, resulting in a reduction of fossil fuel consumption and optimisation of cost

- Reduced drill diameter of T-40 from 115 mm to 89 mm, resulting in an increased drill output from 31m/hr. to 34m/hr

- Using diesel additives, such as Thermol-D in fuel, resulting in a 3-5% reduction in diesel consumption in HEMM

Gagal

- Usage of diesel additive Thermol-D in HEMM fuel has resulted in a 3-5% reduction in diesel consumption