Material Topics

- Capacity Utilisation and Current Demand

- Land Acquisition for Mines and New Operations

- Energy Efficiency

- Compliance to Regulatory Requirement

Stakeholders Impacted

Suppliers

Employees

Government and Regulatory Bodies

Construction Professionals

Focus Areas

Developments and Key Initiatives |

Key Performance Indicators |

|

|---|---|---|

Capacity

|

Expanded capacity through acquisition of Asian Concretes and Cements Pvt Ltd. by ACC Limited. Sanghi Industries Limited and a grinding unit at Tuticorin by Ambuja Cements Limited Capacity expansion projects across country:

|

140 MTPA

Capacity by FY 2027-28 |

Enhancing

|

Commissioned 16.3 MW of Waste Heat Recovery Systems (WHRS) at Ametha Leveraging Group synergies to achieve cost leadership in the industry Continued to implement multiple initiatives such as optimising raw material mix Digital transformation through:

|

376 MW WHRS

capacity by FY 2027-28 28% TSR

by 2030 |

Sustainable

|

Reducing environmental impact of the Company’s operations through:

|

60%

of the overall energy consumption to be powered by renewables by FY 2027-28 1 GW

of Solar and Wind Energy implementation by FY 2025-26 |

Quality

|

State-of-the-art Cement and Concrete R&D facility to ensure complete quality control |

Following BIS

for all products |

Manufacturing Overview

The Company relies on physical infrastructure such as land, buildings, production plants, leased mines, heavy machinery, equipment fleet, furniture, and fittings to support its daily operations.

Clinker production

Cement production

Captive power

generated (Mn units)

Installed capacity of

captive power plants

WHRS generated

(million units)

WHRS Generation

MW Capacity

Thermal Substitution

Rate (TSR) achieved

Clinker Factor

Waste co-processed

Green Power Consumed

Development and Efficiency

The Company has made significant investments to bolster its market presence, focusing on enhancing efficiency, cost competitiveness, and environmental sustainability to gain a competitive advantage. Key measures undertaken include:

Capacity Expansion

- Completed successful acquisition of Asian Concretes and Cements Pvt Ltd with cement capacity of 2.8 MTPA

- Successfully commissioned integrated unit Ametha, bolstering the Company’s annual clinker capacity by 3.3 MTPA and cement capacity by 1 MTPA

- The Company’s capex projects aim to increase cement production by establishing new plants, debottlenecking existing ones, and enhancing efficiencies. The Company recently announced various capacity expansions for blended cement

Brownfield cement Grinding Unit at Sindri, Jharkhand

Greenfield cement Grinding Unit at Salai Banwa, Uttar Pradesh

Seamless Integration of Asian Concretes and Cements Pvt Ltd

The seamless integration of Asian Concretes and Cements Pvt Ltd into ACC, guided by Adani Group’s vision, has been completed. Following the acquisition, plant capacity utilisation rose from 28% to 52% between December 2023 and March 2024. Cement quality is ensured through fully automatic ROBO Lab inspections with NABL accreditation. Employee welfare was prioritised, with safeguarded pay and a new healthcare facility. Measures to enhance safety include Saksham training, a permit-to-work system, and PPE distribution. ACC’s integration and upgrade efforts have improved the overall operational performance, quality standards, employee benefits, and safety protocols.

Plant capacity utilisation rate achieved post-acquisition as of FY 2023-24

Raw Material Security

- To secure limestone needs for various cement plants and for future requirements, the Company participated in auctions

Energy

- The Company implemented waste heat recovery systems across various locations to minimise power costs and promote green energy. The Company is currently installing projects generating 39.5 MW in its plants at Chanda and Wadi

- Reaffirming its commitment to sustainable practices, the Company is continuously increasing the share of Alternative Fuels and Green Power. With an investment of over I 10,000 crore in green power projects, the Company aims to power 60% of its planned 140 MTPA cement capacity through 1 Giga Watt of solar and wind power and 376 MW of Waste Heat Recovery System by FY 2027-28, offering compelling economic advantages

Waste heat recovery system commissioned being installed in Chanda and Wadi cement plants

Manufacturing Performance

The Company has adopted worldclass manufacturing standards by integrating cutting-edge technologies, streamlining production processes, and upholding rigorous quality control measures. The Company is working consistently to boost operational efficiency, reduce costs, and minimise its environmental footprint.

The Company witnessed yet another year of accomplishments as it continued to improve its performance.

Reduction in logistics cost as a proportion of total operating cost

Logistics

The Company has been undertaking several initiatives to rationalise its logistics cost, a key cost component. ACC is aiming to set a new standard by reducing the average primary road lead by 50 km, with network optimisation along with increasing the share of wallet in the closer market. This initiative marks significant progress in the Company’s efforts to optimise warehouse operations. With a strong emphasis on sustainability and cost reduction in logistics, ACC is optimising the transportation mix by leveraging 11 GPWIS rakes for efficient clinker movement from the mother plants. Additionally, ACC has allocated 26 Bogie Covered Fly Ash/Cement (BCFC) rakes to ensure the safe and cost-effective transportation of fly ash from thermal power plants to its facilities. These costsaving measures are primarily driven by effective route planning at the micro-market level, strict adherence to its primary source, renegotiation of commercial terms and the integration of GPS and other technological solutions.

Driver Management Centre (DMC)

The Company has been scaling up of Driver Management Centres (DMCs) and upgrading their deliverables. ACC continued its focus around safety, skill development and driving behaviour management of truck drivers with Driver Defensive Induction (DDI) for all new truck drivers, and Driver Defensive Training (DDT) for all drivers – a mandatory course, repeated every six months.

Engaging with the driver community and counselling them towards safety-oriented behaviour is consistently carried out with daily Tool Box Talk (TBT), Journey Risk Management (JRM) briefing and IVMS (GPS)-based counselling.

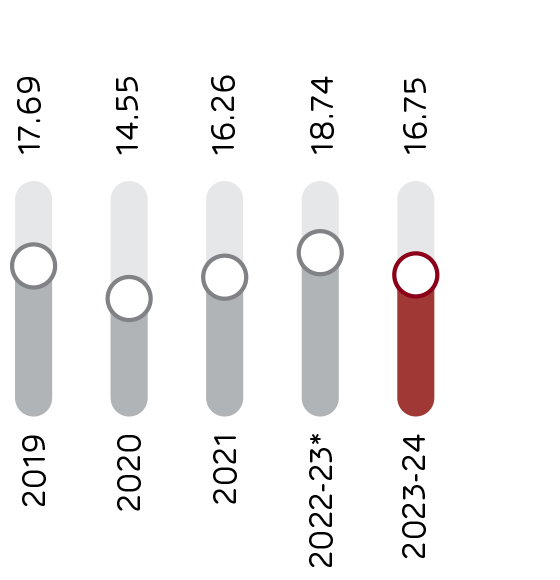

Clinker Production Volume

(MMT)

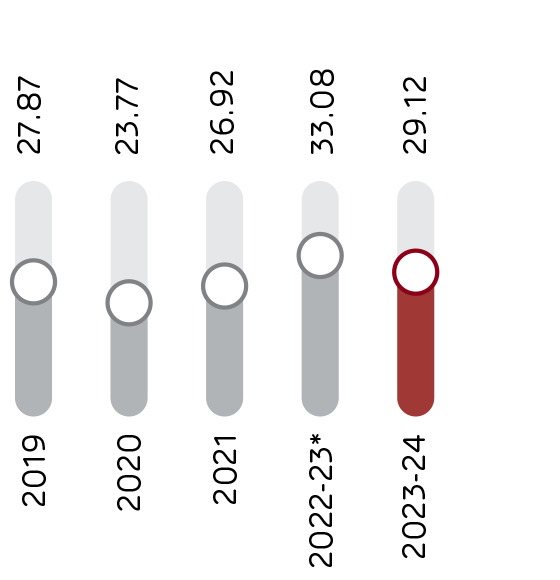

Cement Production Volume

(MMT)

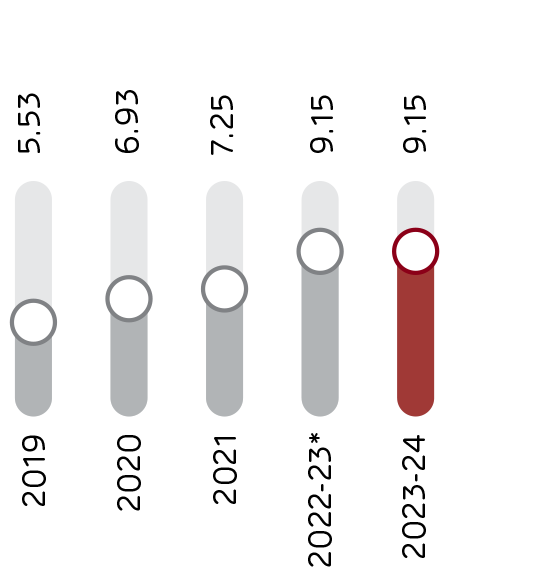

Thermal Substitution Rate

(%)

*Note: The Company had changed its financial year end from December 31 to March 31 in FY 2022-23. Therefore, the figure for FY 2022-23 is for 15 months and not comparable with the figures for the 12 months year ended on March 31, 2024.

Improving Efficiency

ACC remains committed to investing in the crucial facets of its operations, aspiring to emerge as one of the most cost-competitive cement manufacturers in the country. Its comprehensive and strategic initiatives focus on the reduction of clinker factor, improvement in energy efficiency, optimisation of raw material and fuel blends, enhancements to power sources, and the increased1 utilisation of alternative fuels and raw materials within its manufacturing processes.

Energy Efficiency

ACC has implemented several measures to enhance productivity and reduce energy consumption across its operations such as:

- Modified mill internals to improve productivity and decrease energy usage

- Adjusted grinding media patterns, resulting in a reduction in energy consumption during grinding processes

- Modified coolers to enhance heat recuperation, thereby reducing fuel consumption. Inefficient coolers have been replaced with more efficient alternatives, further reducing thermal energy consumption

- Substituted classifying liners in cement mills, contributing to a decrease in electrical energy consumption

- Upgraded its transportation equipment to more energyefficient modes, reducing energy consumption during material movement

- Automated mill and kiln operations using emerging technology to improve specific energy consumption through consistent operations

Reduction in operating cost per tonne of CLC in FY 2023-24

Improving Productivity

ACC has undertaken various initiatives to enhance grinding efficiency and optimise equipment to boost productivity and efficiency:

- Modified grinding circuits, improving grinding efficiency, ensuring smoother and more effective operations

- Focused on enhancing equipment productivity and efficiency through various initiatives Optimised the use of grinding aids to maximise efficiency and productivity, ensuring effective resource utilisation

Increase in Operating EBITDA per tonne of CLC in FY 2023-24

Cost Efficiency

To enhance sustainability and cost-effectiveness, ACC has implemented various initiatives:

- Introduced BCFC rakes to streamline Fly Ash availability and reduce associated costs

- Installed Carbonated Fly Ash (CFA)

- Feeding Systems have been prioritised to further enhance efficiency in resource utilisation

- BCFC has also taken steps to source Flue Gas Desulfurisation (FGD) Gypsum, promoting the use of recycled materials in its processes

- Installed AFR preprocessing and feeding systems instrumental in diversifying fuel sources and reducing reliance on traditional fuels

- Implemented a Gas bypass system which has been undertaken to increase the utilisation of alternative fuels, contributing to a more sustainable and environmentally friendly operation overall

Product Quality Management

ACC takes pride in delivering top-notch product quality, maintaining the highest standards through a rigorous quality management system. Recently, the Company showcased its commitment to innovation by inaugurating a state-of-theart cement and concrete R&D lab facility in Navi Mumbai. Demonstrating its dedication to sustainability, ACC maximised the use of low-grade limestone in cement manufacturing and strategically replaced costly natural gypsum with more affordable by-products without compromising quality.

Additionally, the Company explored environmentally friendly coprocessing for thermal substitution and resource conservation, maximising industrial waste utilisation. Innovative processing techniques enhanced the quality of blended cement across all ACC plants, aligning with market-driven product development efforts to reduce the carbon footprint. Systematic quality benchmarking exercises were conducted for ACC’s products, ensuring consistency and excellence, while automation using analytical equipment ensured data accuracy and compliance monitoring. Further advancements included effective polypropylene bag quality control and automation in bag testing, standardising quality practices across all manufacturing locations through continuous improvement initiatives.

Average Mean Time Between Failures (MTBF) increased from 521 hours

Excellence through AWMS

The Adani Group launched the Adani Workplace Management System (AWMS), which follows the 5S philosophy. 5S is considered the first step on the journey to excellence for an organisation. It is a method of creating a self-sustaining culture which perpetuates a neat, clean, safe, efficient workplace; a method of removing all excess materials and tools from the workplace and organising the required items such that they are easy to find, use, and maintain. AWMS has been rolled out across all ACC’s plants.

Mining

The Company’s dedication to sustainable operations is evident in efforts to enhance equipment productivity, minimise environmental impact during mining activities, and optimise fleet operations through strategic negotiation and stock rehandling minimisation. The Company is implementing these measures to optimise and enhance the efficiency of its mine operations:

- Eco-friendly mining with no blast technique by deploying surface miner in coastal areas

- Adopted Zero Waste mining policies

- Adopting safe practices in each mine during development and operation

- Environment friendly mining operation by deploying mining equipment with minimum exposure of workers to health and occupation hazards

- Proper blending of low-grade and high-grade material for optimisation of resources as well as maximising life of mines

- Conservation of mineral, water and other natural resource materials

Supply Chain and Logistics

During the reporting year, the Company has improved and optimised its logistics cost by leveraging Group synergy. ACC has implemented advanced logistics and fleet management digitalisation for real-time vehicle tracking, enhancing efficiency and leading to optimised logistics expenditure. The Company has also adopted integrated excellence projects for logistics cost rationalisation.

The Company has enabled a seamless supply of raw materials at plants by procuring BCFC and Bulk Cement Carrier Wagon (BCCW) rakes to enhance fly ash availability and bulk cement transportation.

Initiatives Implemented during the Year to Drive the Logistics Journey

Go Direct

Implemented digital solutions to optimise the supply chain simultaneously, expanding the fleet capacity for D2C delivery.

Agile and Automated Logistics Infrastructure

Introduced in-plant automation measures such as advanced tracking and tracing of primary vehicles, resulting in decreased truck turnaround times and a substantial boost in dispatch capacity.

Commercial Excellence

Enabled advanced scientific models to optimise operations and strategically renegotiate freight and handling rates for enhanced cost-effectiveness and profitability.

Push Towards Low-Cost Green Energy

Transitioned from diesel to compressed natural gas and electric fuels to significantly reduce the Company’s carbon footprint while optimising logistics costs for enhanced sustainability and economic efficiency.

Real-time Demand and Supply Optimisation

Integrated cutting-edge digital tools for instantaneous order processing, ensuring precise source matching based on cost-effectiveness and service quality to meet increasing demands.

Digital Transformation

Established a centralised logistics control tower to monitor realtime performance comprehensively and proactively take necessary actions for continual improvement and operational excellence.

Implementing Best Practices with ‘udAAAn’

Under ‘udAAAn’, ACC has implemented numerous result-oriented initiatives across logistics, manufacturing and sales aimed at enhancing the efficiency and quality of its operations. Some of the key initiatives include:

Logistics

- Building EV truck operations with successful trials already conducted

- Improved productivity of fleet through ‘Track & Trace’ solutions

- Optimised and reconfigured warehouses by opening ~40 small capacity warehouses

- Created a dashboard for tracking rail rake with key parameters

- Finalising the logistics dashboard

Manufacturing

- Launched ‘udAAAn Performance Index’ (UPI) to measure manufacturing performance

- Launched ‘Copy with Pride Framework’ to reduce time taken to replicate and maximise benefits

- Conducted intra-plant and inter-plant competitions of completed initiatives to motivate teams and encourage excellence