Material Topics

- Climate and Energy

- Air Quality

- Water Management

- Circular Economy

- Biodiversity Management

- Sustainable Construction

Stakeholders Impacted

Communities

and NGOs

Government and Regulatory Authorities

Suppliers

Channel Partners

Employees

Focus Areas

Developments and Key Initiatives |

Key Performance Indicators |

|

|---|---|---|

Net Zero |

On track to reach net zero by 2050 |

14.8

million tCO2

Scope 1 emissions 0.6

million tCO2

Scope 2 emissions |

Energy

|

Commissioned wind turbines, solar panel farms, waste heat recovery system Adopted newer technologies to reduce carbon footprint |

737 kCal/kg of clinker

Specific thermal energy consumption 13.1%

Energy consumed from renewable and green sources in FY 2023-24 |

Water

|

Increased recycled water and rainwater harvesting usage Developed innovative products that reduces water usage for the customers |

1.0x

Water-positive |

Waste

|

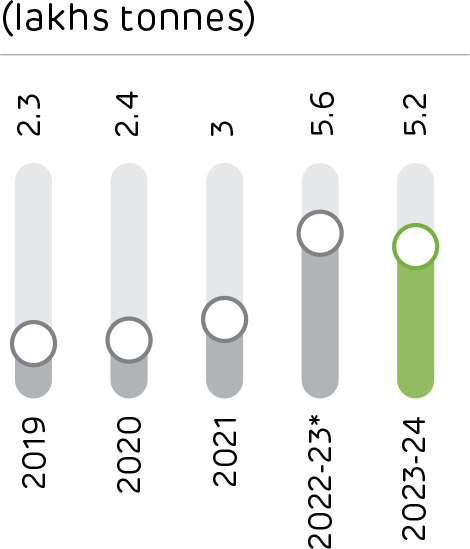

Enhanced use of alternative fuels and raw materials in cement Adopted waste disposal initiatives under Geoclean Adopted initiatives to curb plastic waste through co-processing initiatives |

0.52 MMT

Waste co-processed 7x

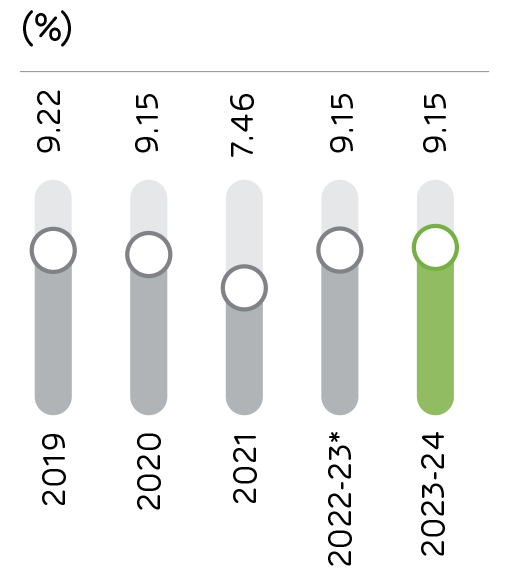

Plastic negative 9.15%

Thermal substitution rate |

Tree

|

On track to grow 5.93 million trees by 2030 |

4.9 million

Trees planted till FY 2024 |

Sustainability Strategy

Sustainability is an integral part of ACC’s strategy, risk management and core offerings. At the forefront of industry-leading standards, the Company champions sustainability and circularity initiatives. This encompasses the development of green products and solutions, effective fossil fuel substitution, and optimisation of processes and logistics.

Environmental Policy and Management System

ACC’s comprehensive Environment Management System aligns policies, procedures and practices with industry best standards, enabling proactive management of climate risks, waste reduction and recycling efforts. The Company actively promotes the integration of climate change measures with national and global policies demonstration its responsibilities to broader environmental initiatives and sustainable practices.

Environmental Policies

ACC has a set of policies concerning the environmental dimension of ESG.

- Climate Change Policy

- Energy Management Policy

- ESG Policy

- Environment Policy

- Water Stewardship Policy

- Resource Conservation Policy

- Bio-Diversity Policy

The policies are applicable to all operations of the Company and the implementation is overseen by the Corporate Responsibility Committee (CRC). The CRC consists of Independent Directors and is accountable to the Board.

All ACC plants have the following management systems in place. The audits take place regularly and the certifications are periodically renewed.

ISO 9001:2015

ISO 50001:2018

ISO 9001:2015

ISO 45001:2018

Performance Highlights FY 2023-24

by 2050 with near-term (2030) targets validated by SBTi

Renewable and Green Energy Used

Scope 1: 513 kg/tonne of cementitious material

Of waste-derived resources

Water-positive

Plastic negative

Trees planted till FY 24

Green products

Specific thermal energy consumption

Climate and Energy

Climate Strategy

The Company is mitigating climate change risks across its operations, aligning with national and global policies and commitments such as Nationally Determined Contributions under the Paris Agreement and the United Nations Sustainable Development Goals. ACC’s climate strategy emphasises on reducing carbon footprint, enhancing resilience, integrating climate considerations, and striving for Net Zero emissions. Initiatives include increasing renewable energy use, conserving water, reducing waste, and implementing energy efficiency measures.

Climate Risks

Climate Governance

ACC has a comprehensive Climate Change Policy that mandates managing climate risks and adopting global best practices. Oversight is provided by the Corporate Responsibility Committee (CRC), which reviews progress quarterly. The ESG team develops the ESG agenda and supports implementation at the Company level. The Risk Management Committee oversees sustainability and ESG risks, reflecting the increasing importance of climate risks in enterprise risk management.

TCFD Disclosure

ACC adheres to the Task Force on Climate-Related Financial Disclosures’ (TCFD) framework and International Sustainability Standards Board (ISSB) S2 climaterelated disclosures. The Company has undertaken comprehensive Climate Risk Assessment for all its plants. Based on identified risks, scenario analysis is undertaken. The risk mitigation and adaptation strategy is designed to protect interests of stakeholders and business operations. ACC’s TCFD disclosure includes disclosing climate-related governance, strategy, risk management and associated metrics and targets.

Climate Risk Management

ACC conducted a comprehensive climate risk assessment study for all its plants and conducted Shared Socioeconomic Pathways (SSP) scenario analysis for the identified risks. Anticipated financial risks at both site-level and organisationlevel were studied. Based on these findings, climate strategy and actions were designed to mitigate the negative impacts of climate change and enhance business resilience.

Physical Risks

Physical risks fall under acute and chronic physical risks – acute risks arising from climaterelated hazards like temperature extremities, pluvial flooding, coastal flooding, fluvial flooding, drought, cyclone, water stress etc. and chronic risks from changing weather patterns and rising mean temperature and sea level etc. These can cause damage to assets, supply chain disruptions and other impacts. Detailed analysis of physical risks is carried out for all plants of the Company.

Physical Risks

Aligned with the TCFD framework, ACC considers the following risks:

- Policy and legal

- Technology

- Market

- Reputation

Climate Related Scenario Analysis

ACC conducted scenario analysis on Shared Socioeconomic Pathways (SSP) to assess climate risks. These scenarios, ranging from SSP1-1.9 to SSP5-8.5, help understand various possibilities and levels of risk, uncertainty, and volatility. The goal is to ensure assets and operations can effectively manage climaterelated risks and capitalise on emerging opportunities.

Risk Mitigation

ACC implements a range of measures to mitigate climate risks. These include routine inspections, emergency response plans, health and safety protocols, and effective communication strategies. Annual weather forecasts inform global supply chain decisions to prevent delays. Measures against heat waves include scheduling minimal outdoor work during peak summer, offering flexible hours, and conducting mock drills. Adequate insurance coverage protects against asset damage or material loss due to extreme weather events.

Internal Carbon Pricing

Internal Carbon Pricing (ICP) plays a vital role in ACC’s strategy to reduce GHG emissions and manage financial impacts from climate regulations. By quantifying risks at each site and aggregating them, the Company assesses lowcarbon investments and selects energy-efficient technologies for new projects. With an ICP calculated on the basis of per metric tonne of CO2 (tCO2) reduction, ACC allocates funds for renewable projects and energy efficiency measures, aligning with stakeholder expectations.

Greenhouse Gas Emissions (GHG)

The Company monitors and reports carbon emissions from all manufacturing locations, including integrated cement plants, mines, grinding units, and bulk cement terminals, aligned with IPCC, CSI and GHG Protocol greenhouse gas accounting standards. The direct GHG emissions of cement plants almost entirely consist of CO2. The contribution of other non- CO2 greenhouse gas emissions is almost negligible. investments in new, more cost-effective filters and by improving the efficiency of operating plants.

Total Scope 1 emissions in

FY 2023-24

Total Scope 2 emissions in

FY 2023-24

Net Zero Commitment

ACC is at the forefront of climate action and sustainability within its sector, aiming to significantly contribute to India’s net zero emissions goal. Committed to achieving net zero emissions by 2050, the Company’s near-term targets for 2030 are already validated by the Science Based Targets initiative (SBTi) in line with a well-below 2°C trajectory. While awaiting validation for its 2050 targets, focusing primarily on Scope 1 and 2 emissions, which constitute approx.. 90% of its total emissions of its total emissions, ACC also aligns with the Global Cement and Concrete Association (GCCA) Roadmap for Net Zero Concrete by 2050.Commitment to SBTi.

The Science Based Targets initiative (SBTi) mobilises companies to transition to the lowcarbon economy. It is a partnership between CDP, the United Nations Global Compact, the World Resources Institute (WRI) and the World Wildlife Fund (WWF).

ACC Limited is Committed to SBTi. The Company’s 2030 targets are duly validated and approved by the SBTi and can be referred at https:// sciencebasedtargets.org/targetdashboard. Its targets are in line with a well-below 2°C trajectory.

SBTi Commitment

ACC Limited commits to reduce Scope 1 GHG emissions 21.3% per tonne of cementitious material by 2030 from a 2018 base year*. ACC Limited also commits to reduce Scope 2 GHG emissions 48.4% per tonne of cementitious material within the same timeframe.

*The target boundary includes biogenic emissions and removals from bioenergy feedstocks.Performance on SBTi targets

| GHG emissions | Scope 1 | Scope 2 |

|---|---|---|

| Target Year 2030 |

465 kg/tonne

Cementitious material |

10.4 kg/tonne

Cementitious material |

| Performance FY 2023-24 |

513 kg/tonne

Cementitious material |

21 kg/tonne

Cementitious material |

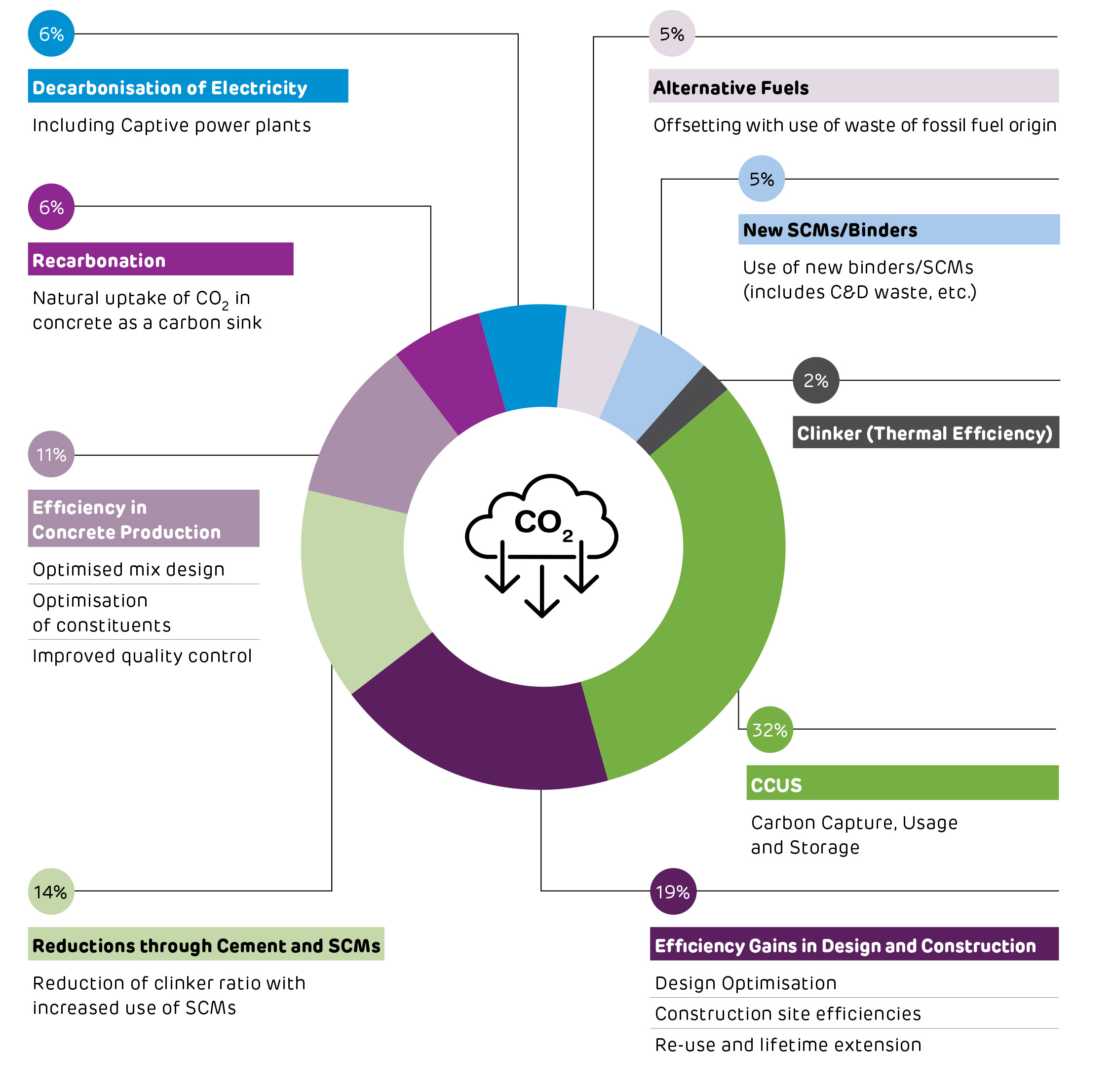

Net Zero Roadmap

ACC has a net zero roadmap which aligns with its SBTi commitment and GCCA 2050 roadmap for the cement and concrete industry.

Decarbonisation Levers at ACC

| Scope 1 | Scope 2 | Scope 3 |

|---|---|---|

|

- Use of renewable energy - Use of green energy – waste heat recovery systems (WHRS) |

|

Future Initiatives

|

||

Energy Management

Cement is an energy-intensive sector. Efficient energy management is essential in controlling operational costs. The Company regularly monitors the energy performance at all its sites, which is discussed in the monthly management meetings. Efforts are made to continuously improve the energy performance of the Company.

Energy Consumption

The Company is minimising its energy footprint across its diverse range of businesses. The operations leverage a blend of energy sources, including fossil fuels, alternate fuels, renewable energy and Waste Heat Recovery Systems (WHRS). Rigorous monitoring of energy consumption at various facilities and equipment enables us to analyse consumption patterns and structures, allowing us to strategically prioritise and implement energy conservation initiatives.

Clinker factor

Total energy consumed

in FY 2023-24

cementitious material

Energy intensity

Thermal Energy

Energy consumed from

renewable and green sources in

FY 2023-24

Specific electrical energy consumption

Climate and Energy Management Initiatives

In climate and energy management, the Company has undertaken multiple initiatives such as:

Enhancing the energy efficiency of operations

Using alternative fuels (Co-processing)

Waste heat recovery systems

Renewable energy

Green products

Enhancing Energy Efficiency

The Company consistently invests in reducing both thermal and electrical energy consumption per tonne of cement produced. Several plants are part of India’s Perform, Achieve and Trade (PAT) scheme, The specific thermal energy consumption is steadily reducing overtime.

| Year | Thermal Energy Efficiency (kCal/b kg of clinker produced) |

|---|---|

| 2019 | 747.8 |

| 2020 | 742.2 |

| 2021 | 742.2 |

| January 2022 - March 2023 | 753.8 |

| 2023-24 | 737 |

Thermal Substitution Rate*

PAT Scheme to Reduce Specific Energy Consumption

Perform, Achieve and Trade (PAT) is a regulatory instrument in India to reduce specific energy consumption in energy intensive industries. It has an associated market-based mechanism to enhance cost effectiveness by certifying excess energy savings which can be traded.

Under PAT, industries having high specific energy intensity are identified as designated consumers within certain key sectors, which must file energy consumption returns every year and regularly conduct mandatory energy audits. The essential tasks in the mechanism are to set the specific energy consumption norms for each designated consumer in the baseline year and in the target years, devise a verification process for specific energy consumption, find ways of issuing the energy savings certificates, operationalisation of the trading process for energy savings certificates in addition to the compliance and reconciliation process for energy savings certificates. The outcomes are in the form of energy savings and subsequent carbon savings.

Renewable and Green energy

ACC is investing in renewable and green energy to mitigate its carbon footprint, reducing dependency on conventional electricity sources. The Company plans to increase its green power share to 60%, a significant expansion in the industry. Major investments are directed towards solar and wind energy, along with Waste Heat Recovery Systems (WHRS). This strategic move aligns with ACC commitment to environmental sustainability and reducing greenhouse gas emissions.

| Year | Renewable and Green Energy (Cumulative installed capacity-MW) | ||

|---|---|---|---|

| WHRS | Wind | Solar | |

| 2023-24 | 46 | 19 | 34 |

| 2024-25 | 95 | 19 | 34 |

| 2025-26 | 95 | 19 | 34 |

| 2026-27 | 95 | 19 | 34 |

| 2027-28 | 158 | 19 | 34 |

| 2028-29 | 179 | 19 | 34 |

| 2029-30 | 179 | 19 | 34 |

This ambitious target reflects the Company’s determination to reduce its carbon footprint, promote clean energy practices and contribute to a more sustainable future. These initiatives are pivotal parts of a broader vision which will help ACC to achieve the leading share of renewable and green energy among its peers.

Alternative Fuels (Co-processing)

ACC takes a sustainable approach to managing industrial, agricultural, and municipal waste. Leveraging co-processing technology, the Company has access to preprocessing and co-processing facilities across India, each equipped with waste storage areas, feeding arrangements and laboratories. Through these advanced facilities, the Company efficiently manages large volumes of waste, ensuring the recovery of energy and recycling of waste materials.

As part of its commitment to sustainability, ACC is scaling up investments to modernise and upgrade its pre-processing and coprocessing facilities. Expert teams continue to offer solutions to likeminded customers across diverse sectors, facilitating the utilisation of higher volumes of waste in the manufacturing process.

The state-of-the-art pre-processing facilities play a crucial role in converting highly heterogeneous waste streams into a homogenised mix through sequential operations such as blending and shredding. This process ensures that the waste is transformed into an alternative resource, reducing reliance on traditional fossil fuels. Through sustained upgrades to the waste management infrastructure, ACC has continued to increase its dependence on alternative fuels. In the reporting period, 0.52 million tonnes of alternative fuels were consumed. These efforts underscore ACC’s commitment to sustainability and responsible waste management practices.

Thermal Substitution Rate

Alternative fuels consumed

Quantity of Co-processed Waste

Green Products

ACC stands as the industry leader in producing and distributing blended cement, renowned for its eco-friendly properties with significantly reduced clinker content. By incorporating materials like slag and fly ash, ACC not only contributes to environmental preservation but also facilitates the construction of robust and enduring infrastructure nationwide. Currently, the Company’s portfolio comprises green products, constituting 96% of its offerings. The green products of the Company are duly certified by GRIHA.

Air Emissions

In addition to greenhouse gas emissions, the combustion of fuel during operations produces air pollutants such as nitrogen oxides (NOx) and sulphur oxide (SOx), contributing to the environmental impact of the industry. Furthermore, business activities contribute to particulate emissions through fuel combustion and vehicular movement.

ACC has implemented air pollution control measures, including Electrostatic Precipitators (ESP) and bag filters for both flue and process emissions. The Company has installed closed conveyor belts for material transfer. To manage dust, dust suppression methods such as water sprinkling on the roads is implemented. Continuous Emission Monitoring Systems (CEMS) have been installed at all plants to constantly monitor SO2, NOx, particulate matter, and any other significant emissions from kilns/raw mill stacks. The results are digitally displayed across all monitoring locations.

Green products

| Parameter | Unit | 2023-24 (April’23 to Mar’24) |

|---|---|---|

| NOx | Tonnes | 9,721 |

| SOx | Tonnes | 469 |

| Particulate matter (PM) | Tonnes | 268 |

| Persistent organic pollutants (POP); Volatile organic compounds (VOC); Hazardous air pollutants (HAP); ozone depleting substances (ODS); Direct mercury emissions, others | NIL | NIL |

Water Management

Water is a scarce natural resource and plays a pivotal role in the SD 2030 plan and is a key material topic and a fundamental pillar. While cement manufacturing primarily employs a dry process, the Company judiciously uses water for cooling, dust suppression and human consumption within its operations. It has already achieved a water-positive status that is nearly twice its water consumption and is working towards increasing this to 5x by 2030.

Furthermore, the Company has gained international recognition for its leadership in water security by CDP. Recognising the critical importance of responsible water management, the Company has instituted a robust water stewardship policy. The overarching goal is to safeguard and conserve water resources, prioritising ACC’s operations and its communities.

Objectives of Water Stewardship Framework

Seek to minimise reliance on freshwater resources for operations

Ensure water security for communities residing beyond their immediate boundaries

Aim to continue being water-positive through sustainable water management practices

Waste water

discharged

Water

recycled

Fresh water

consumption from

rainwater harvested

Water-positive

Water Withdrawal and Consumption

While the Company’s operational sites depend on various water resources, it acknowledges the significance of reducing its impact on shared water sources. Continuously assessing and refining its water withdrawal processes, the Company strives to adopt efficient and sustainable water management practices. Through proactive measures, ACC ensures responsible and judicious use of water resources.

Total Water Consumed

Water Intensity

ACC Cements has undertaken an ambitious target to reduce the intensity of freshwater utilisation per tonne of cement produced. Water intensity has significantly improved over the years, and the Company is likely to achieve its target much ahead of time. These achievements underscore its relentless pursuit of water efficiency and responsible resource utilisation.

Per tonne of cementitious material in FY 2023-34

Water Recycling and Reuse

As part of its sustainability commitment, the Company has implemented robust wastewater recycling and reuse practices across its units. These initiatives aim to maximise water efficiency, minimise reliance on freshwater sources, and reduce the water footprint. Effective recycling systems are in place, with recycled water utilised for dust suppression and gardening purposes.

Water recycled/reused

Wastewater Discharge

ACC treats and recycles wastewater generated at its plants for gardening and dust suppression, with no discharge outside the premises. These practices effectively minimise and conserve the Company’s water footprint, showcasing its commitment to sustainable water management.

Total wastewater discharge

Rainwater Harvesting and Conservation

The Company actively engages with developers and communities to promote water conservation practices that align with its water management strategy. It has implemented the following initiatives:

- Utilised many of its closed mine pits for water conservation by rainwater harvesting and groundwater recharge to ensure water for livelihood

- Revived village ponds through engagement with rural communities

- Partnered with governments for various water conservation projects like checking dams

- Engaged with developers for rainwater harvesting projects

- Developed and implemented in-house modular (zero-water) curing solution at around 3,300 sites, saving around 39 million litres of water

- Engaged in rainwater harvesting across communities to ensure drinking water security

Rainwater harvested for consumption

Waste Management and Circular Economy

ACC works towards sustainable resource consumption, waste reduction, and circular economy principles. The Company prioritises waste management by surpassing regulatory standards and implementing industry best practices to minimise negative environmental impacts. Compliance with applicable environmental laws ensures responsible waste handling across operations.

Waste Generation

ACC undertakes several waste minimisation practices. Waste generated across its operations undergoes collection and segregation at the source, distinguishing between hazardous and non-hazardous categories. These waste types are then stored separately in designated yards. Moreover, the Company maximises the utilisation of waste as alternative raw materials, diminishing reliance on mined resources and averting their disposal into the environment.

Following types of wastes are generated by the Company:

- Plastic waste

- E-waste

- Bio-medical waste

- Construction and Demolition waste

- Battery waste

- Other hazardous waste

- Non-hazardous waste

Total waste generated

Waste Management Measures

The Company prioritises waste minimisation by emphasising recycling and reuse initiatives. Proper disposal of e-waste, bio-medical waste, and scrap is ensured through authorised recyclers registered with regulatory agencies. Most plants employ co-processing of plastic waste and used oil in cement kilns, eliminating waste disposal to landfills. Some key waste management initiatives include:

- Plastic waste is mainly disposed through co-processing by the Company and a very small quantity like burst bags through authorised scrap dealers

- Bio-medical waste is disposed through incineration of biomedical waste at authorised Common Bio-medical Waste Treatment Facilities

- E-waste and battery waste is recycled through authorised recyclers

- Hazardous waste (used oil) is reused at plant and or is coprocessed in cement kiln and the quantity which cannot be co-processed is sent to common incinerator

- Scrap is sold to authorised vendors

- Mining overburden is repurposed and used for backfilling within the mines

of cementitious

material

Hazardous waste

sent to

land fill

Being Plastic Negative

The Company has proudly embraced a ‘Plastic Negative’ ethos which has resulted in it removing 7x times more plastic waste from the environment through co-processing, than what is added through the use of plastic packing bags. This has resulted in a minimising plastic pollution.

Plastic negative

Waste-derived Resources

The Company significantly reduces its reliance on mined resources by utilising a substantial amount of waste materials from other industries as alternative raw materials. This approach not only minimises environmental impact by preventing waste disposal but also promotes sustainable practices in resource management.

Waste-derived resources FY 2023-24

Biodiversity Management

Biodiversity management holds significant importance in the Company’s materiality assessment, recognising the resilience of healthy ecosystems against natural disasters. Vital ecological services crucial for both businesses and society are better protected with robust biodiversity.

ACC addresses its operational impacts on biodiversity through a comprehensive biodiversity policy. This framework guides the identification and evaluation of biodiversity-related risks across project sites, aiming to minimise ecological footprints and promote conservation efforts.

Stage 1

Biodiversity Risk Screening

This assessment aims to identify any sensitive biodiversity areas that the business operations may impact. The Company avoids undertaking operations near the World Heritage Sites, protected areas, sanctuaries, and biosphere reserves. The Company’s operating sites are not adjacent to indigenous peoples’ territories.

Stage 2

Biodiversity Impact Assessment

As part of its commitment to biodiversity conservation, the Company integrates biodiversity impact assessment into the environmental impact assessment process for projects requiring clearance from regulatory bodies such as the Ministry of Environment, Forest, and Climate Change (MOEFCC) or State Environment Impact Assessment Authority (SEIAA).

comprehensive baseline studies on flora and fauna are conducted at all mandatory sites, focusing on endangered and nationally protected species within the project’s influence area. ACC evaluates potential impacts or risks to biodiversity resulting from project activities, with these studies available on the PARIVESH portal of the MEFCC, Government of India. Key potential risks assessed include:

Upstream

- Disturbance to the habitat from land use change and construction activities

- Introduction of invasive species because of the movement of goods and vehicles

Direct Operational

- Risks of pollution

Downstream

- Movement of vessels, traffic, cargo handling that may generate significant noise and vibration disrupt the behaviour, feeding patterns and communication of species

Stage 3

Biodiversity Management Plan

ACC has developed a robust biodiversity management plan aimed at safeguarding and enhancing biodiversity in the vicinity of its operations. This plan, informed by detailed baseline studies and assessments of project impacts on biodiversity, encompasses various measures such as habitat protection, species conservation, ecosystem restoration, stakeholder engagement, and ongoing monitoring. ACC bolsters biodiversity, mitigates adverse effects and actively contributes to biodiversity conservation and sustainable utilisation in its operational areas. The Company collaborates with local experts and forest departments to formulate comprehensive biodiversity action plans with tangible targets across sites, ensuring proactive action based on assessment findings.

Key Aspects of the Company’s Biodiversity Management Plan

- Improving degraded habitats across sites through targeted habitat management plans

- Working closely with the community and government bodies to adequately manage the planted and rehabilitated areas

- Partnering for the management of any other adjoining offset areas

- Turning regenerated areas into natural habitats by adopting new forestry practices

- Carrying out mining operations and raw material transportation only during the daytime near protected areas

- Providing mine tippers with a multi-cap covering system and covered

Initiatives for Biodiversity Conservation

ACC proactively implements measures at its plants and mining sites to ensure biodiversity conservation and enhancement Multiple initiatives are undertaken as discussed below.

Tree Plantation Targets:

The Adani Group has pledged on the World Economic Forum’s Trillion Trees Platform (1t.org) to grow 100 million trees by 2030. As a part of this target, ACC will grow 5.93 million trees by 2030.

No Net Loss to Biodiversity:

ACC aims to align with the No Net Loss to Biodiversity approach with The Taskforce on Nature-related Financial Disclosures (TNFD) framework to guide its efforts in preserving biodiversity

Signatory of IBBI:

ACC’s participation as a signatory to the India Business and Biodiversity Initiative (IBBI) is facilitated by the Confederation of Indian Industry (CII) and Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. This collaboration exemplifies the Company’s dedication to engaging with fellow businesses and stakeholders in collective endeavors aimed at fostering biodiversity conservation and sustainability.

Green Belt around Mining Sites:

The establishment of green belts in and around the Company’s plant and mine areas has transformed the landscape into greener habitats. These green belts serve to mitigate the adverse effects of mining activities by reducing dust pollution and absorbing carbon emissions, contributing to environmental sustainability.

Water Harvesting in Mine Pits:

Water conservation in mine pits in the rainy season helps recharge the groundwater table; the increased availability of water enables people in the water-scarce regions of Gujarat and Rajasthan to grow multiple crops during a longer period of the year, improving their prospects of earning livelihoods. It also preserves the biodiversity of the region. Moreover, numerous migratory birds visit these sites.

At ACC Gagal, over the years, the barren brownish patch of mine has been rehabilitated into a mango orchard. It has become one of the greenest areas of the Bilaspur district in the State of Himachal Pradesh and is an attraction to the visitors of plant. Mining operations were started at Barmana Hill in the year 1984. Later, the mining was shifted to Gagal Hill, where the existing active mining is under progress. As the mineral extraction at Barmana Hill was abandoned for limestone extraction, the reclamation and rehabilitation of the abandoned mines at Barmana Hill was initiated in the year 1990.

An area of 1.05 hectares was reclaimed and converted into a green patch. More than 200 saplings of Mango (Mangifera Indica) & Kher (Acacia Catechu) were planted in the reclaimed mines area and as on date 190 nos. trees are present. This has yielded numerous benefits and advantages for the ecosystem and biodiversity. By planting Mango and Acacia catechu species, the area has witnessed a remarkable resurgence in natural life. These trees serve as vital habitat and food sources for a diverse array of wildlife, ranging from birds to insects and small mammals. Furthermore, the roots of these trees play a crucial role in stabilising soil, preventing erosion, and promoting water retention, thereby creating conducive conditions for the growth of various plant species. This restoration effort has not only enhanced the biodiversity of the region but also improved the overall ecological health and resilience of the ecosystem, fostering a more sustainable and balanced environment for both flora and fauna to thrive. The mango crop is distributed among the employees and stakeholders every year.

Responsible Mining

ACC adheres to responsible mining practices to safeguard the environment and biodiversity around its mines. Limestone is sourced from captive mines near the Company’s integrated plants through sustainable extraction methods and innovative operational practices.

All mines eternally employ controlled blasting with highprecision electronic detonators to enhance safety and reduce environmental impact. Scientific mining technologies ensure mineral conservation, and drilling is performed with dustsuppression measures. Haul roads are maintained to minimise dust emission, and at a few mines where limestone material is transported by road through covered tippers to eliminate spillage and dust emission during transportation. Health and safety measures are strictly followed across all mining sites. Green belts around the mines and plant areas reduce dust pollution and preserve biodiversity.

ACC team members are trained to work with the communities. Overburden/waste material is disposed of responsibly, and some sites have become habitats for migratory and local avifauna. Water conservation efforts in closed mine pits contribute to groundwater recharge, benefitting local livelihoods and water tables.

Regulatory Compliance

Recognising the significance of regulatory compliance for responsible and sustainable business operations, ACC adheres to a comprehensive range of environmental regulations across its sectors. The Company ensures all necessary permissions and approvals are obtained to meet these obligations, monitoring compliance effectively through the Legatrix software. Some of the key environmental regulations applicable to its operations include:

- Environmental clearances

- The Water (Prevention and Control of Pollution) Act, 1974

- The Air (Prevention and Control of Pollution) Act, 1981

- Noise Pollution (Regulation and Control) Rules, 2000

- The Environment (Protection) Act, 1986

- Hazardous and other Wastes (Management & Transboundary Movement) Rules, 2016

- Solid Waste Management Rules, 2016

- Bio Medical Waste Rules, 2016

- Plastic Waste Management Rules, 2016

- E-Waste Rules, 2016

- The Construction and Demolition Waste Management Rules, 2016

ACC’s commitment extends beyond mere compliance, as it strives to excel and set a benchmark among its industry peers regarding regulatory adherence and best practices.